HydroDirector Module

- About the product

- Functional

- Delivery set

- Installation

- Pumping speed of the pump connected to the HydroDirector module

About the product

HydroDirector is an advanced automation and data management solution that has been

designed to optimize hydroponic systems. With HydroDirector, you can collect data from pH, EC and Water Temperature and have complete control over your hydroponic system, and set up alerts to notify you when certain conditions are met, or something goes wrong. This enables you to adjust your system accordingly to achieve optimal growing conditions for your plants.

Functional

-

Control up to 48,000 dosing pumps in one system by adding extra Modules.

-

Single Module can handle 3 pumps and 3 hydroponic Sensors.

-

pH, EC, Water Temperature levels control.

-

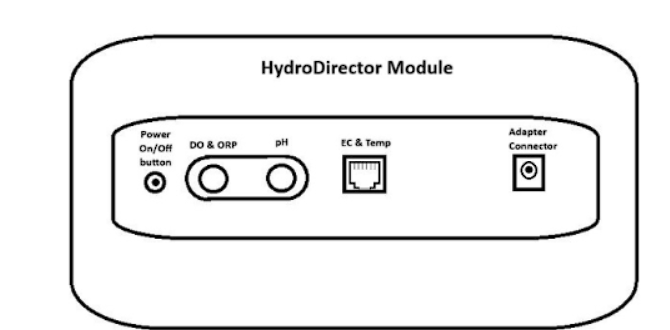

Module has 3 connectors for sensors: 2 round BNC connectors and 1 square RJ12 connector.

-

Customizable Alerts: Set notifications for critical parameter changes, ensuring prompt action when needed to maintain ideal growing conditions.

Delivery set

-

A module;

-

Metal holder;

-

Connector 1,5 A (needs power adapter).

Installation

Caution

Module are not water-resistant, but this module now has manual seeling with tape, this is done to prevent liquid from getting inside the module. Use protective covers for added safety. Ensure compatibility with your electrical system (220V or 110V).

Choose the right location for each module:

Mount module using the included metal bracket and power supply. Near your fertigation room or water reservoir. Ensure 5mm outer diameter pipes are available for dosing pumps, with a maximum distance of 9 feet (2.7 meters) to fertigation tanks.

Connect sensors first, then power the module.

Pumping speed of the pump connected to the HydroDirector module

The Pump on the HydroDirector module is specifically designed to pump 200 ml of water per minute. Since the density of fertilizers and other agricultural liquids can be higher than that of water, this factor must be taken into account when setting up the operating parameters. A denser liquid may result in a lower actual flow rate, meaning that the pump might dispense less volume than expected per unit of time. Therefore, when configuring the system, the client must adjust the rule accordingly to ensure accurate dosing and proper functionality.

For example, common agricultural liquids that may have a higher density than water include:

-

Liquid fertilizers;

-

Pesticides and herbicides;

-

Plant growth regulators;

-

Micronutrient solutions;

-

Organic extracts.

Each of these substances has a different viscosity and density, which may require adjusting the pump settings to achieve the correct application rate.